Tweaking the temperature of the exhaust gas with a mini pipe can help us breathe better – less particle matter, less pollution, cleaner air

Automobiles allowed a future of easy commute; however, they threw a curveball on air purity. In any motor vehicle, the air-fuel mixture is ‘sparked’ to combust and create a thrust force to power the engine. The remaining burned gas is released as exhaust. Millions of solid and liquid particles (particulate matter) and poisonous gases cloaked in these black exhaust fumes, infiltrate our body and cause irritation and breathing disorders. With an increasing number of automobiles on the road, regulations on vehicle pollution are getting more stringent. The re-engineering of the exhaust system to micromanage the type of particles to be released will be a real game-changer.

Particulate matter present in the gas or air stream is in constant motion, either by diffusion, collision (randomly) or under the influence of temperature or current (specifically). When these particles settle and accumulate (fouling) on the surface or within any engine parts, they hamper engine performance. The closed environment of engines during operation is usually hot; in such a scenario, the temperature is the predominant factor that influences the particle mobility. The movement of particles from a higher to a lower temperature is referred to as thermophoresis. A study on the transport behavior of particulate matter under thermophoresis can help in developing control measures for exhaust emission.

The mechanical engineers from K J Somaiya College of Engineering and Indian Institute of Technology, Mumbai, completed a study on the thermophoretic deposition in the diesel engine. “An add-on system with temperature gradient can help in the collection of particles less than 1 micron and release fewer particles loaded exhaust to the atmosphere,” says Dr. Siddappa S. Bhusnoor, Professor of Mechanical Engineering and the lead researcher of the study.

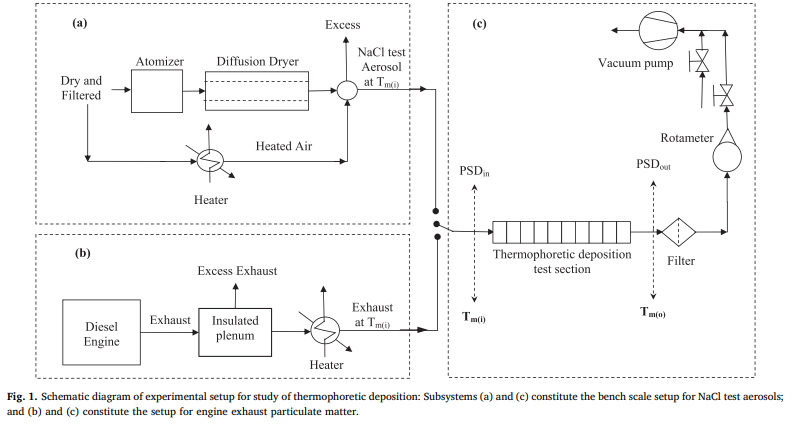

A comparative study of particle mobility (of both NaCl aerosols and diesel engine exhaust particulate matter) under varying gas temperature and flow regimes (Re) was carried out. Particulate matter of varying sizes was passed through a steel pipe of 1m length; conventional natural cooling established a decrease in the pipe wall temperature. This changed the momentum of the particles as they move along the pipe. Laminar air-flow conditions guaranteed thermophoresis as the influencing force for particle mobility. The maximum deposition of particles less than 1µm was found to be at 360 °C and lowest at 170°C at Re of 500 (NaCl) and 400 (exhaust), respectively. With the mini-steel pipe in place, NaCl aerosol showed a reduction of particulate matter by 30% and that of exhaust gas by 32%.

.png)

Hot gas streams are integral for the operation in many processes of manufacturing; they are laden with particulate matter. The deposition of the particulate matter on the internal surface of the machines can interpret its working and decrease the quality of output, leading to financial loss. Particulate matter control devices will help automobile industries, coal-based power plants, cement industries, metal industries, and similar industries enhance productivity as well as keep a check on air quality and pollution control.

Download this Article

Download this Article

Open PDF in Browser

Open PDF in Browser